One of the major engineering challenges of our time in Germany as a highly developed industrial country is the provision of high-strength, high-efficiency components for a wide variety of applications in transport engineering, machine construction, and infrastructure.

Forming processes play a key role in the manufacture of such components made of metal materials. Not only do they enable the economical production of geometrical shapes with reproducible high quality, but they can also influence important component properties. This means that different forming processes and production sequences can lead to identical product geometries, but different component properties for the same component material. So far, the reasons for this are only partially known. While deformation-induced hardening, residual stresses, and the microstructure influenced by a possible heat treatment are controllable and can be used to increase the performance of the component, this does not apply to damage. So far, it is not known in which way the damage is influenced by each individual forming process, how it changes along the process chain, and which influence it has on the component behavior. For this reason, the degree of damage of a component and the effect on the component behavior are generally estimated by generously dimensioned empirical safety factors when designing the component and process.

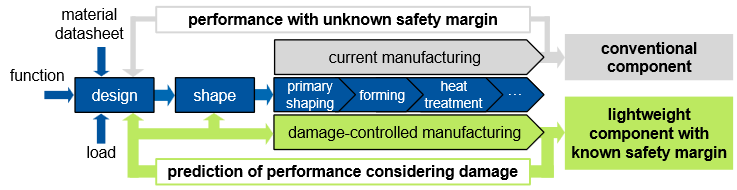

Classical component design without consideration of damage

Two direct consequences result from this:

-

When dimensioning components manufactured by forming technology, lightweight construction potential is wasted because of the forming-induced (pre-)damage and, thus, the safety margin can not be exactly quantified.

-

When designing the forming process, not all influences on the performance of the component are considered. Accordingly, the process design does not take place with the provision of the targeted adjustment of a desired performance.

In order to fully utilize the potential of modern material concepts and forming processes for the realization of optimally efficient components, a paradigm shift in dealing with damage is absolutely necessary.